Automatic Manual CNC Robotic Polishing

Buffing Deburring Abrasive Belt Grinding |

Alvar Process Technologies YOUTUBE Channel.

C.N.C. Robotic Polishing and Buffing Workcells.

We supply machinery and systems for surface preparation and refinement. Deburring, Grinding, Polishing, Buffing, Brushing

Manualy operated to automatically loaded and unloaded turn-key systems.

| For

Sales, Service and Support Contact us |

Delivery program Automatic

/ Robotic Systems ;

STANDARD - STANDARD 4 STATIONS - MAXI - X

STATIONS

Delivery program

Manual belt polishing / buffing machines ;

HP 960 DL / F - SMF

350 /F - SMT 300

Years of experience

If you would like to further

investigate the advantages of automation in surface finishing, please call us, we

will be happy to assist.

We have supplied quite a number of finishing systems for abrasive belt grinding and polishing / buffing. For over 20 years with many machines in successful operation throughout the

world. Starting as a small subcontract polishing outfit, Stahl

developed automatic polishing and grinding machines and copying

attachments to enable more efficient completion of his own contracts.

Stahl had grown over the years to become a leader in automating

abrasive belt polishing and buffing.

The success of this

equipment is based upon a foundation of logical and necessary operating

principles.

Proven Robot

Technology

The Robot must be designed to automate any

finishing operation currently requiring skilled manual polishers or

finishing personnel.

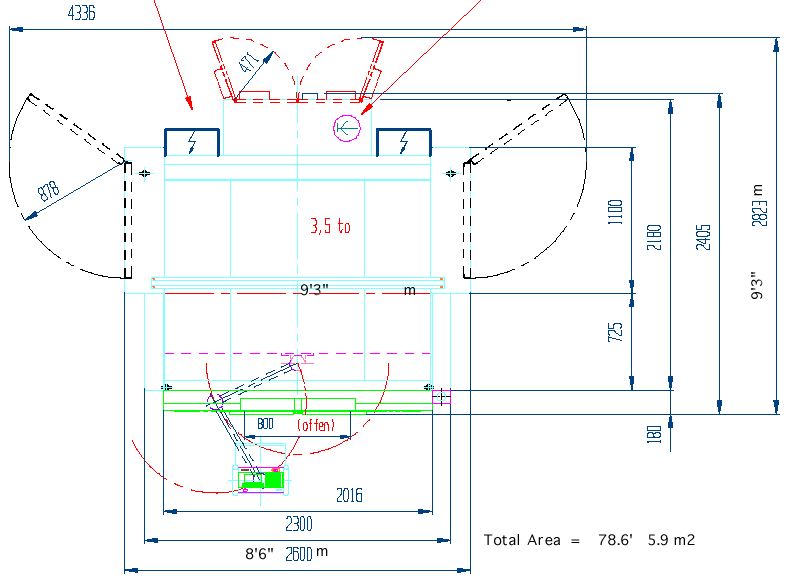

Complete Self Contained

Operating Environment

The Robot is built into the

machine frame incorporating extraction ducts , pneumatic part loading

doors , illumination and emergency stop safety circuit. The Robot

cell keeps noise within a comfortable 84db during grinding or polishing

operations, there is no dust pollution due to the enclosed extraction

environment and no possibility of operator injury.

Consistently small installation

layout.

The Robot has a footprint of less than 6 m2.